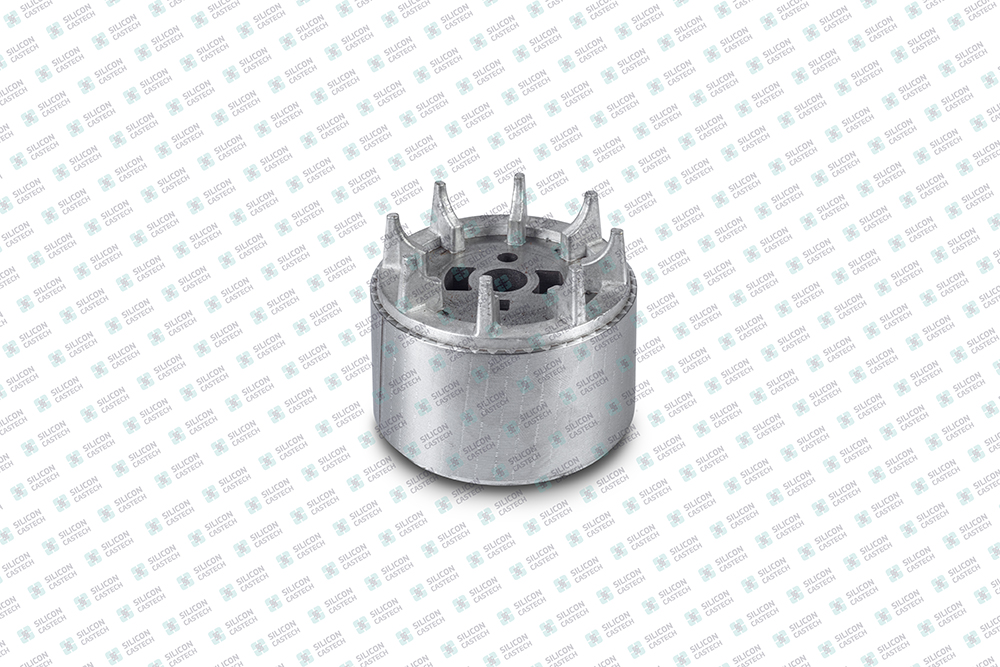

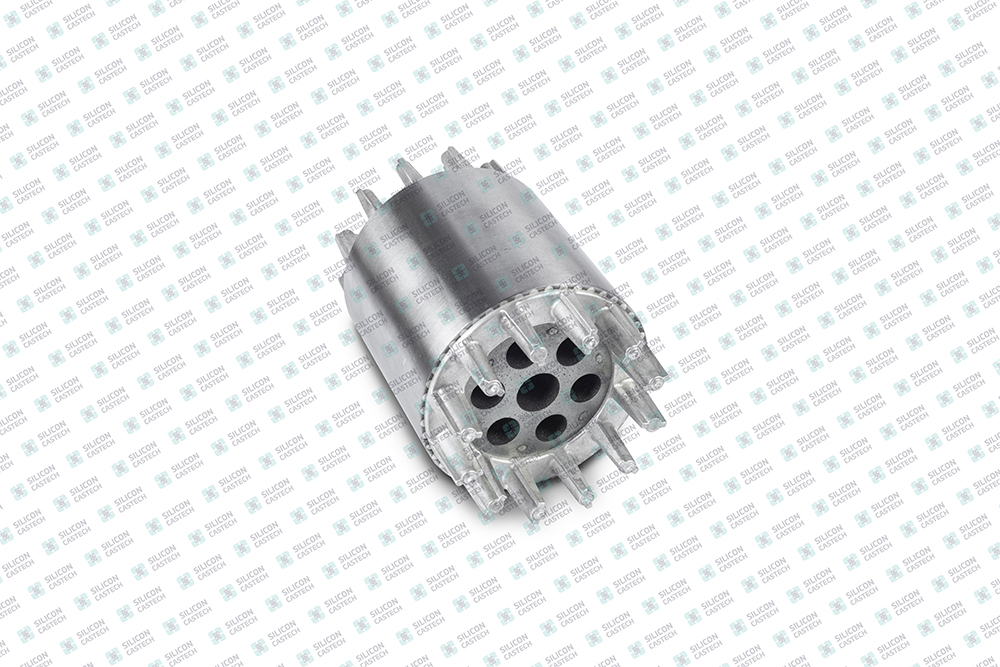

High Pressure Die Casting (HPDC)

Customers select their grade of aluminium which is diecast as per specifications. We use top end HPDC Machines such as Zitai, Yizumi and Mutal machines to produce the best quality castings.

Buffing & Trimming

Once we remove the casting from the mold, the trimming process is carried out. Next, our wheel type belt, type buffing/sanding or shot blasting machines give a superior finish to the produced castings.

Machining

Our machining facility consists of high end fully automated CNC machines which provide precise machining in the die casted parts, maintaining the accuracy in microns. During this stage, extreme care is taken to ensure the external and internal diameters meet the exact specifications. We also have Special Purpose Machines (SPMs) for high-accuracy drilling and tapping to meet specific requirements.

Lacquering & Special Services

We have a lacquering facility to apply lacquer in all casting with rotors to prevent rusting. On special request, we also offer painting or powder coating.

Mold/Die Making

This is the first stage of any project with a customer approaching us with their requirements. We collaborate closely to work out the kinks and to plan out the correct mold for the project. Under special circumstances existing mold of the customer can be used as well.